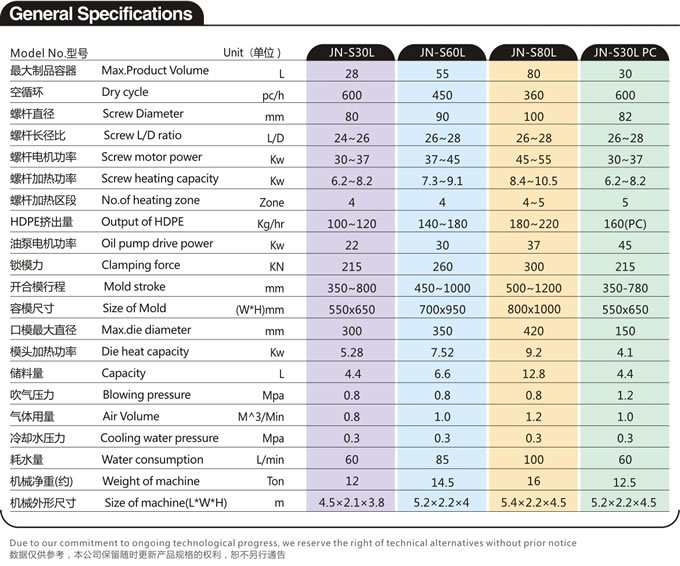

90 hollow blow molding machine

Equipment superiority:

1. Screw design for efficient mixing, ensuring uniform plasticization.

2. The extruder is driven by a variable frequency motor, which has low energy consumption.

3. The mold closing action is a horizontal movement mode operated by a linear slide rail.

4. Lock the mold cylinder in the center position of the template to ensure even force distribution, improve product quality, and extend the mold's service life.

5. The opening and closing of the mold is controlled by high-strength guide rods, increasing the locking force and providing high stability and efficiency for machine operation.

6. The sturdy and efficient first in, first out storage mold head has precise material distribution inside, making it easy to change colors or materials.

7. Advanced design can eliminate material degradation in the flow channel, help avoid cavity sagging, and eliminate weld lines.

8. Precise time microprogram control ensures that products fully meet requirements, reduces product weight, and shortens production cycles.

9. The front and rear movable extrusion mechanism design makes mold replacement convenient and fast.

10. Multi functional downward blowing air seat, convenient for forming special products.

11. Innovative robotic arm design that can automatically retrieve finished products.

Contact Yikebo

Company Address::Building 1, No. 689 Qiaotouwang Village, Chengjiang Street, Huangyan District, Taizhou City, Zhejiang Province

E-mail:caiyongzhen125@163.com

Phone:150 6760 4096